Resource Library

Technology alone won't get you where you want to go. And that's why we won't ever just offer technology.

Filter by

Resource type

- Poster presentation

- Flyer

- Application Note

- Article

- Brochure

- eBook

- Primary Literature

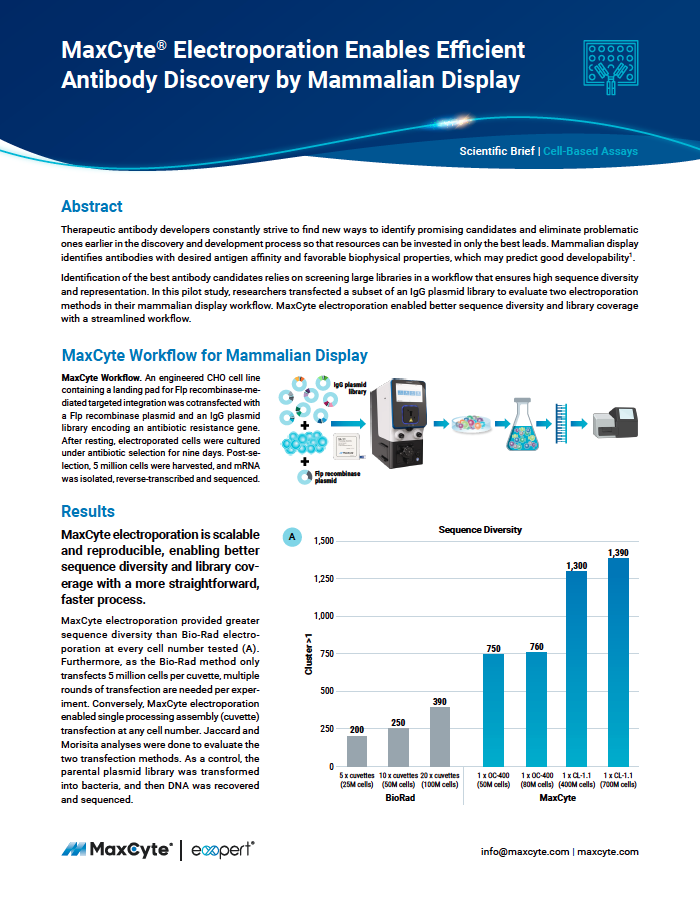

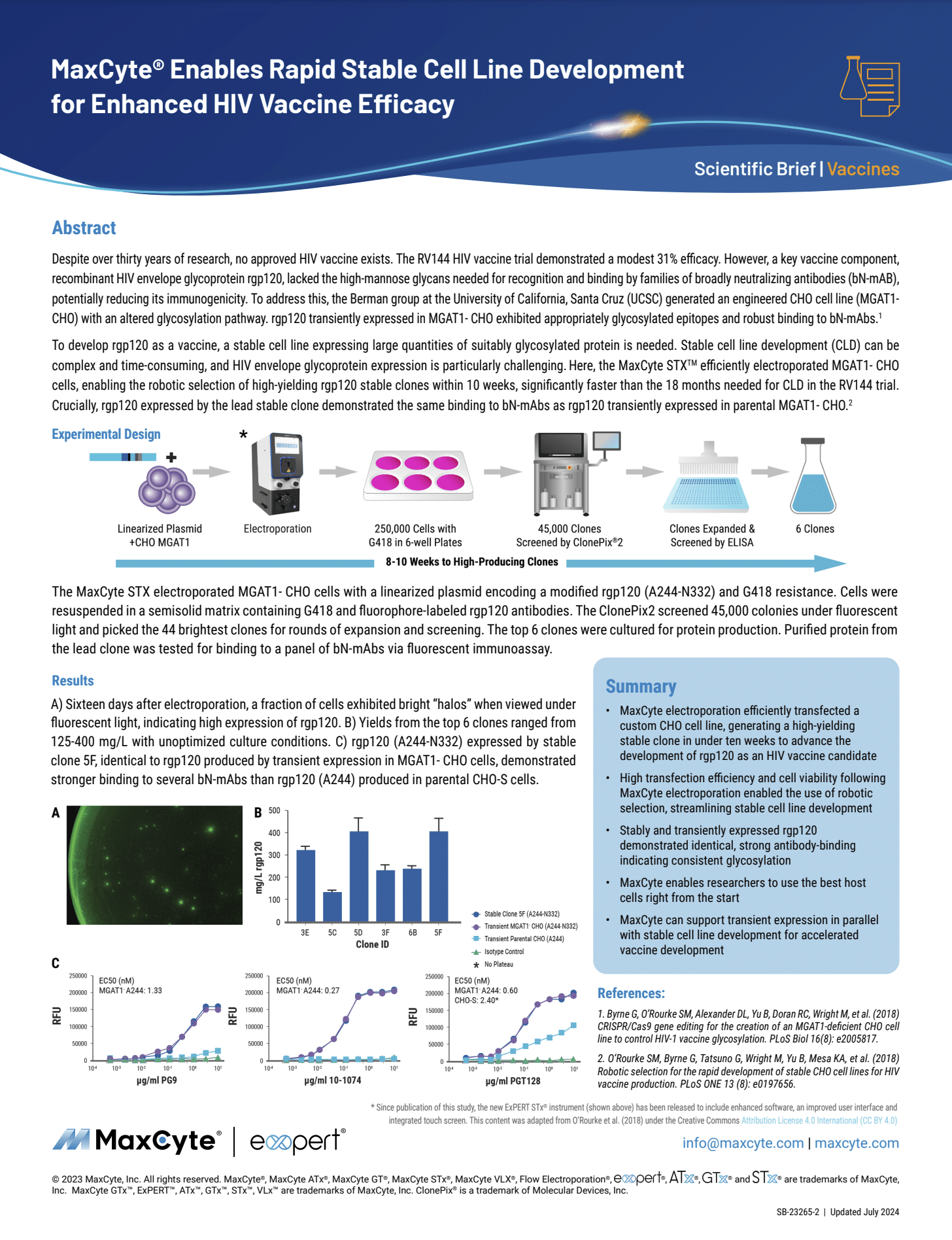

- Scientific Brief

- Scientific Poster

- Webinar/Presentation

Application

- Virus-like Particles

- Cell Based Assays

- Cell Line Development

- Cell Therapy

- CRISPR/Gene Editing

- Protein Production

- Stem Cells

- Vaccines

Cell type

- B Cells

- Cancer Cell Lines

- Cardiomyocytes

- CHO

- Dendritic Cells

- Fibroblasts

- HEK293

- HSPCs

- Insect Cell Lines (S2/Sf9/Sf21)

- ion channels

- iPSCs

- Keratinocytes

- MSCs

- Neurons

- NK Cells

- NPCs/NSCs

- Other Mammalian Cell Lines

- PBMCs

- T Cells